A study from 2019 reported that an estimated 7.2 million electric cars are on the road, with the number growing yearly. Electric vehicles are popular because they can save on expensive gas and reduce your carbon footprint. More and more manufacturers are creating electric cars, but it is not without its challenges. Companies need to create proper electromagnetic interference (EMI) shielding.

There is an increasing number of sources of EMI. Electric car manufacturers must shield their products from external and internal EMI sources. The large battery packs in electric vehicles are an internal source that requires EMI shielding.

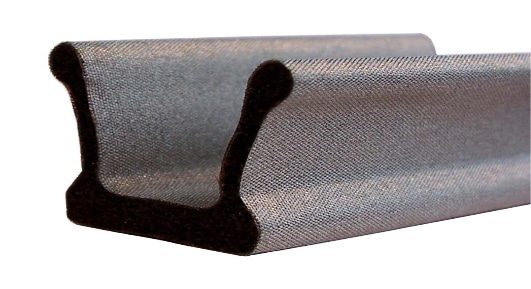

The type of material used for EMI shielding electric cars is important. High-quality products are essential to ensure you’re providing consumers with the best. Materials such as wire oriented silicone and conductive foam are excellent choices for creating large-scale gaskets needed in electric cars. We use a manufacturing process called extrusion to create these gaskets. Through this process, the EMI shielding material is pushed through a die to cut it into the shape needed.

Extrusion is also used when creating EMI shielding for electric vehicles because of the production speed. It’s important to manufacture EMI gaskets at the same rate as the vehicles built.

When considering EMI shielding for your electric car, passenger safety should be at the top of your list. The batteries used to run electric cars are huge and constantly emit electromagnetic radiation. Since passengers sit on top of this battery, EMI shielding is essential. To ensure passenger safety, create EMI shielding surrounding the vehicle’s battery.