Electromagnetic interference has always been an issue that impacts the lifespan and performance of electronic equipment. Even though EMI has always been a problem for electronics, the issue is getting significantly worse for one main reason: more EMI is in our everyday environment now than ever before. This is related to the ever-growing number of electronic devices. EMI occurs naturally, but its effect on electronics is often minimal. To combat ever-present EMI, electrical engineers rely on EMI gaskets (shielding gaskets) to solve this problem.

Simply put, EMI gaskets close gaps that exist in equipment enclosures. This creates a seal that keeps EMI out and prevents EMI from escaping into the environment. It is essential to recognize that EMI shielding works both ways: to prevent EMI from entering and from leaving.

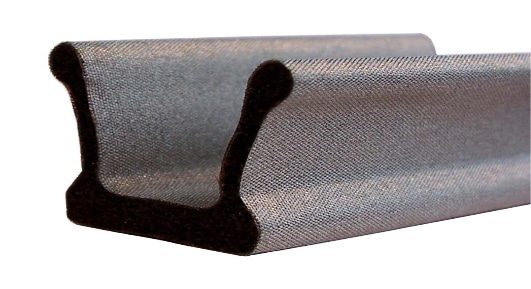

There are many different EMI gaskets to choose from, and each type has different characteristics. Beryllium copper is used to create highly conductive and versatile gaskets when superior performance and consistent stability are needed. On the other hand, wire mesh EMI gaskets are used to create a permanent seal.

EMI gaskets are widely used, although they are hardly ever seen. Daily, most people use computers and commute by some form of powered vehicle (Car or bus). Many of the automotive control systems found within a single car benefit from integrating EMI gaskets. A modern car has upwards of 50+ electronic systems placed within a confined space. Without EMI protection, these electronics would generate high levels of EMI that interfere with one another.

EMI gaskets are an excellent option for protecting electronics from the harmful effects of electromagnetic interference. For more information on custom design and gaskets, you should not hesitate to give our team a call.