Electromagnetic interference is a real problem despite few people knowing it exists. Because of shielding and gasket solutions, the potential rampant problems of EMI are kept under control. EMI is an inescapable problem because it exists in nature and is caused by all electronics. These two factors create an ever-present problem that needs addressing. There are several solutions designers and engineers can apply to their design, and one of the most common is EMI shielding fabrics (i.e., conductive fabric tapes).

Electromagnetic interference is a real problem despite few people knowing it exists. Because of shielding and gasket solutions, the potential rampant problems of EMI are kept under control. EMI is an inescapable problem because it exists in nature and is caused by all electronics. These two factors create an ever-present problem that needs addressing. There are several solutions designers and engineers can apply to their design, and one of the most common is EMI shielding fabrics (i.e., conductive fabric tapes).

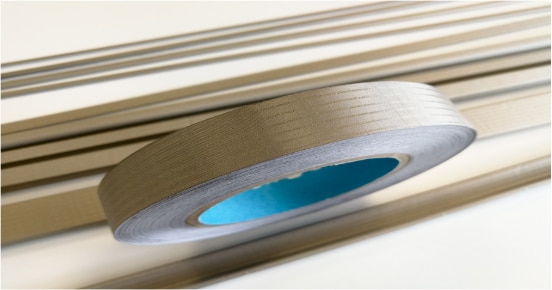

In short, shielding fabric reflects and absorbs RF signals negatively affecting shielding effectiveness. When creating EMI shields, the thickness of the material is important, but shielding fabrics, as a coating, are meant to be thin and reflective (thickness has no bearing on reflectiveness). Using shielding fabrics constructed from copper and nickel (or a combination of both) is a great option for achieving high reflection. These shielding fabrics are also light, which helps to keep the overall weight down. To further assist with making design easy, materials are available with several backing styles, which include:

- Conductive Adhesive

- Non-Adhesive

- Hot Melt

Although there are standard sizes (dimensions), custom fabrication is available for orders depending on company needs. Both conductive adhesive and hot melt shielding fabrics can be laminated and bonded into intricate, geometrical shapes.

EMI shielding fabrics are often found around seams, joints, and frames. The material is sometimes used in architectural shielding (ceilings and walls). For more information on conductive fabric tape, you should reach out to our team today.